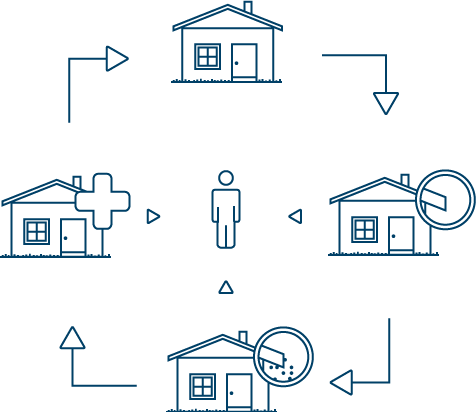

The IO philosophy

The generic research philosophy is to employ an umbrella perspective focusing on real-life product materials and surfaces and investigate how these surfaces interact and change on a macro- and micro-scale during use in a given environment, and quantify whether the use of such surfaces can influence the surrounding environment via dispersed metals. Through collaboration with experts in other disciplines, the fate of dispersed metals is assessed and its implications from an environmental and toxicological perspective are addressed. The research approach enables an in-depth fundamental understanding on prevailing mechanisms for specific case studies and exposure scenarios of relevance for the given product and its application and data relevant for risk assessment and management.

Working interdisciplinary and together as a team, utilises the strength in each individual member, is a key concept within the IO group to create a dynamic and inspired working environment.

The product

An in-depth understanding of the use and characteristics of the product/material before it is exposed is vital knowledge for understanding its behaviour during its entire service life. This kind of information includes chemical composition, surface treatments and coatings, surface finish, heat treatments, ageing, transportation, handling, to mention a few. All these parameters together with the prevailing environmental conditions during service will have a significant impact on the performance of the product. These aspects are always considered and explored prior to any IO group investigation.

Corrosion and surface chemistry/characteristics

In order to understand and elucidate how and why a metal/alloy surface is oxidized and corroded in a given environment and how this changes its surface characteristics and corrosion properties, the IO group performs in-depth surface analytical studies to investigate such changes. This is accomplished by analysing changes with time of the surface before and after exposure in the given environment using a combination of a wide range of different surface sensitive spectroscopic and microscopic techniques combined with electrochemical and chemical techniques.

Except for in-depth surface characterization, it is also essential to acquire knowledge on the composition and characteristics of prevailing exposure conditions in order to be able to link generated knowledge with specific exposure parameters.

Metal release monitoring

Investigations of the diffuse dispersion of metals from product surfaces, e.g. from outdoor constructions, are performed by the IO group through systematic mechanistic and quantitative studies of metal runoff from metal panels exposed at various test sites around the world and also from existing roofs and facades of buildings. By exposing well defined surfaces and collecting the runoff water, the total amount of metal runoff is quantified and evaluated.

The total metal concentration as well as the chemical form of released metals (metal speciation) is determined and characterised using different chemical techniques. Modelling of changes in chemical speciation as a function of differences in aqueous chemistry is performed in parallel. Studies are also performed at laboratory conditions to investigate the importance of specific exposure parameters on corrosion and the metal release process.

This work related to atmospheric corrosion has resulted in an international standard, ISO 17752:2012 Corrosion of metals and alloys – Procedures to determine and estimate runoff rates of metals from materials as a result of atmospheric corrosion.

Toxicological considerations

In order to assess whether the diffuse dispersion of metals from oxidised and corroded surfaces may pose a risk on the environment and on human health, it is essential to address their environmental interaction and fate. Such deliberations require for instance in-depth knowledge and understanding of how the chemical form (speciation) of the released metal changes in contact with different solid surfaces and with organic material upon environmental entry.

An understanding of how these surfaces can and may act as sinks for released metals is also imperative to evaluate if the released metal may pose adverse environmental effects.

The interaction between metals released through the runoff process and the environment is of large importance from a risk perspective and is studied by the IO group in collaboration with ecotoxicologists and soil scientists, to mention a few experts. The IO group was one of the first research groups world-wide who studied both the influence of the environment on atmospheric corrosion and metal runoff of metals and alloys used in outdoor construction and vice versa, the environmental impact of atmospheric corrosion and metal runoff.

Downstream users

By communicating unbiased scientific data the IO group provides industry, legislators, stake holders and the general public on an international arena with important information that they can use to evaluate the potential impact of the product on the environment.

When the product is finally used for its intended application it is important that the downstream user can feel confident that the decisions made concerning the products use and regulations are based on relevant scientific data.